The design of new CNC-machined parts

Our company has a team of experienced engineers and designers specialized in the design and manufacturing of CNC-machined spare parts and forming tools for tray sealing machines in the food industry. Our customers rely on us to ensure that their machines operate efficiently and reliably, ensuring smooth production.

We initiate the design process by sitting down with the customer and understanding their needs and requirements. We also take into consideration any relevant industry standards and regulations to ensure that our parts meet the highest quality standards.

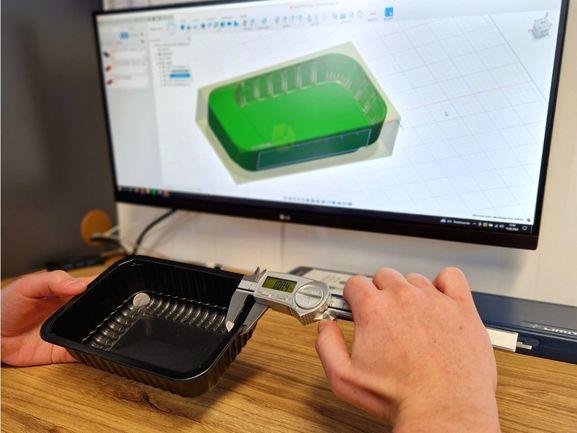

Our designers then use the latest CAD/CAM software to create 3D models of the parts. This software allows us to design and test the parts in a virtual environment, ensuring that they meet the customer's requirements.

The advantage of using CAD/CAM software

A major advantage of using CAD/CAM software is the ability to make changes quickly and easily. When the customer suggests changes to the parts, our designers can quickly respond and adjust the design without causing any delays in production. This flexibility allows for efficient collaboration and ensures that the final product meets the customer's requirements accurately and in a timely manner.

Once the design is complete, we use the CAD/CAM software to generate a CAM program that controls the CNC milling machine. This software allows us to automate the production of the parts, resulting in higher accuracy and consistency of the milled components. By utilizing the CAM program, we can precisely define the toolpaths, cutting speeds, and feeds, ensuring that each part is machined to the desired specifications. This automation not only improves the overall efficiency of the manufacturing process but also reduces the potential for human error, resulting in reliable and precise CNC-machined parts.

The latest CAD/CAM technology

Our company regularly invests in the latest CAD/CAM technology to ensure that we can deliver the best possible results to our customers. We take pride in utilizing industry-leading technology to develop innovative designs for the food packaging and processing industry.

Overall, the use of CAD/CAM software is crucial for designing new CNC-machined parts for the packaging industry. t allows us to produce precise and reliable replacement parts and forming tools for tray sealing machines compatible with Multivac, Variovac, Sealpac, Webomatic, Mondini, and CFS Tiromat Meeting the highest quality standards and ensuring smooth production for our customers is our top priority.